Welcome to the world of time management, where every minute counts and every task has a deadline. As you navigate through your daily schedule, you may wonder: should I be a master scheduler or a production planner? As a time management teacher, I understand your struggles and I’m here to help. Today, we will explore the differences between a master scheduler and a production planner. By understanding these roles, you will gain insights into how you can enhance your productivity and achieve your goals more efficiently. So let’s dive in and discover your productivity powerhouse!

The Master Scheduler is the maestro of time management. They orchestrate the entire schedule, ensuring every task and project is executed seamlessly. With exceptional organizational skills and attention to detail, master schedulers maintain a bird’s eye view of all the moving parts, allowing them to allocate resources effectively and prevent schedule conflicts.

On the other hand, the Production Planner is the conductor of efficiency. They focus on the production process, analyzing data and identifying bottlenecks to optimize operations. Production planners excel at creating streamlined workflows, coordinating with suppliers, and ensuring the production line runs smoothly, ultimately maximizing output and minimizing waste.

Why should you care about becoming a master scheduler or production planner? The answer lies in the benefits these roles provide for your personal and professional life. By mastering scheduling or production planning, you will:

1. Take control of your time. As a master scheduler or production planner, you will gain the power to prioritize tasks effectively, ensuring that you allocate your time wisely and accomplish what matters most to you.

2. Enhance your productivity. By understanding scheduling or production planning, you can identify inefficiencies, eliminate time wasters, and streamline your workflow, resulting in increased productivity and output.

3. Reducing stress and overwhelm:

An optimized schedule or production plan reduces stress and overwhelm. It provides a clear roadmap, allowing focus on work without constant frazzlement.

4. Achieving goals faster:

Mastering scheduling or production planning aids in meeting project deadlines and increasing production targets. It helps propel forward and achieve goals faster, with less effort and more efficiency.

Now that we’ve provided an overview of the master scheduler and production planner roles, decide which route resonates with you most. Are you ready to take control of your time and unleash your productivity powerhouse? Stay tuned for our upcoming articles, where we will delve deeper into each role, providing you with practical tips and strategies to excel as a master scheduler or a production planner. The power to transform your productivity is in your hands!

Master Scheduler vs Production Planner: A Detailed Comparison

When managing the production process, companies employ a master scheduler and a production planner. These roles have distinct differences in responsibilities and focus. Understanding these differences optimizes the production workflow and ensures smooth operations.

A master scheduler is responsible for creating and maintaining the production schedule. They consider factors like customer demand, resource availability, and capacity to create a plan that outlines when and how each product should be manufactured. The master scheduler determines the sequence of production orders and ensures its adherence throughout the process.

However, a production planner focuses on the day-to-day activities of the production floor. They work closely with the master scheduler to execute the production plan by coordinating with different departments and allocating resources. The production planner oversees the timely completion of production orders, monitors inventory levels, and addresses any issues that may arise during the production process. While both roles are essential to production, the master scheduler has a broader scope and strategic focus compared to the production planner’s operational focus. The master scheduler ensures that the production schedule aligns with the company’s goals and objectives, while the production planner takes care of daily production operations to maintain smoothness.

The master scheduler and production planner have distinct but complementary roles in the production process. The master scheduler creates the production schedule and the production planner carries out the plan on a daily basis. By understanding these responsibilities, companies can optimize their production workflow and achieve greater efficiency.

Overview

A master scheduler and a production planner are vital roles in a manufacturing organization. Their primary goal is to ensure smooth and efficient production processes, meeting customer demand while minimizing costs.

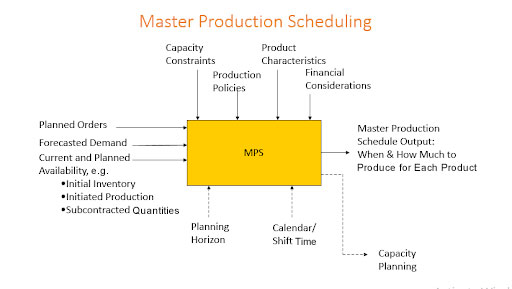

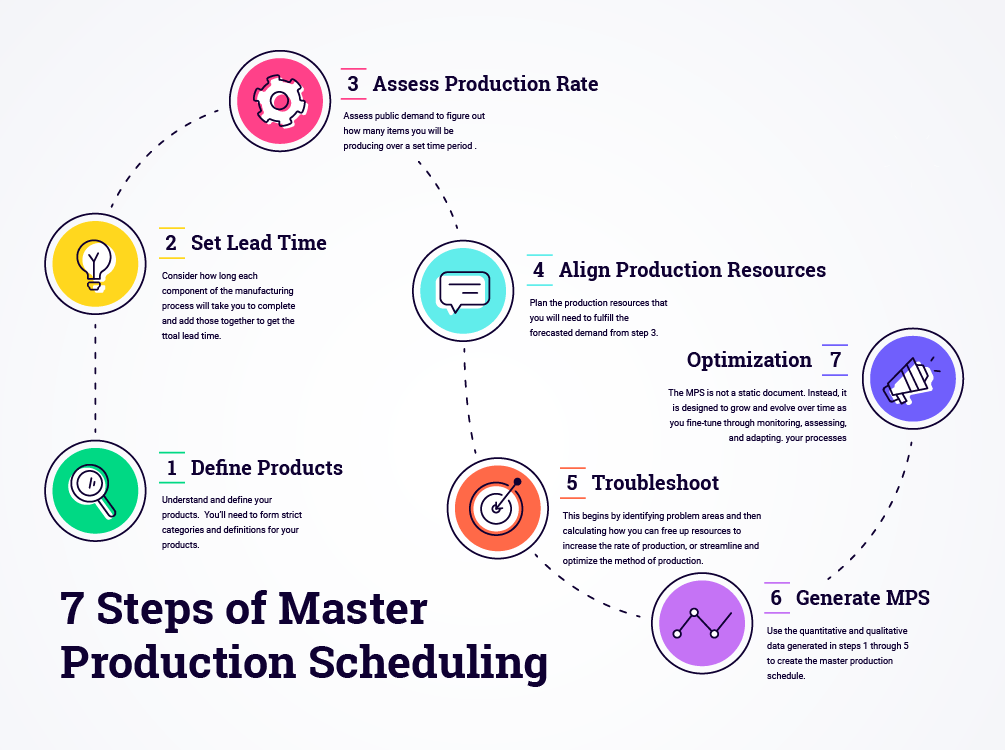

The master scheduler creates and maintains the master production schedule (MPS), in which the products to be made, their quantities, and deadlines are outlined. Considering customer demand, production capacity, and inventory levels, the master scheduler formulates an optimized schedule. They collaborate closely with sales, operations, and procurement teams to gather required information and make informed decisions.

The production planner takes the MPS from the master scheduler and determines the specific processes, resources, and timelines required for production. They ensure that materials and resources are available and coordinate with different departments for smooth production flow.

In summary, the master scheduler creates and maintains the overall production schedule, while the production planner breaks it down into detailed plans and ensures execution. Both roles are critical for efficient, on-time production that meets customer demand.

Below is a table summarizing the key responsibilities of a master scheduler and a production planner:

JOB TITLE: Master Scheduler & Production Planner

—

Creates and maintains the master production schedule (MPS) by breaking it down into detailed production plans.

Considers customer demand, production capacity, and inventory levels when optimizing the schedule. Determines specific processes, resources, and timelines for production.

Collaborates with various departments, gathering necessary information to make informed decisions, ensuring material availability and coordinating with departments for smooth production.

Focuses on the overall production schedule and detailed plan execution.

Key Features or Points

When comparing a master scheduler and a production planner, it’s important to consider key features.

The master scheduler creates a high-level production schedule that considers overall product demand and resource availability. They prioritize orders, manage capacity, and ensure production targets are met. The production planner focuses on detailed planning and execution, working closely with the master scheduler to create actionable plans for each production stage.

Another key feature is that the master scheduler provides a holistic view of the production schedule, while the production planner focuses on the details. The master scheduler analyzes the overall demand and resources, strategically determining the optimal schedule. The production planner then converts this schedule into tasks, considering factors like equipment availability and labor capacity.

The master scheduler also monitors and adjusts the schedule as needed, considering factors such as customer demand changes, supplier delays, or equipment breakdowns. The production planner collaborates closely with the master scheduler to implement these adjustments and keep production on track.

Both the master scheduler and production planner play crucial roles in the production process. The master scheduler focuses on strategic planning and decision making, while the production planner handles the detailed schedule execution. Working together, they ensure production targets are met and customer demands are fulfilled.

Practical Tips or Strategies

– Effective communication is crucial: The master scheduler and production planner must maintain open lines of communication with one another and other departments involved in the production process. Schedule regular meetings and provide status updates to address any issues or changes that arise.

– Define roles and responsibilities: Clear understanding of respective roles and responsibilities is vital for both the master scheduler and production planner. This prevents confusion and ensures that each individual knows their planning and scheduling expectations.

Technology can be used to streamline the planning and scheduling process. Utilizing available tools and software, the master scheduler and production planner can improve efficiency and accuracy. Prioritizing tasks based on their importance and urgency is crucial for completing critical tasks on time and minimizing delays or disruptions in production.

Continuously monitor and review: The master scheduler and production planner should continuously monitor the production process, reviewing schedules to identify potential issues or areas for improvement.It enables proactive adjustments to be made, minimizing the impact on production.

Foster a collaborative work environment: The master scheduler and production planner should work as a team, fostering a collaborative environment.This promotes effective communication, problem-solving, and decision-making, essential for successful planning and scheduling.

Personal Perspective or Case Study

In my experience as a production planner, I have worked closely with the master scheduler in a manufacturing company. The master scheduler creates a production schedule that maximizes efficiency and meets customer demands. As a production planner, I monitor progress, ensure materials and resources are available, and make adjustments when necessary.

Working with the master scheduler is crucial for maintaining smooth production flow. We collaborate daily, discussing the production schedule status, identifying bottlenecks, and finding solutions. The master scheduler has a big picture view of the production process and makes informed decisions about scheduling changes or prioritizations.

One case study that I remember is when a supplier faced a delay in delivering a critical component. This could have disrupted the entire production schedule and put customer deliveries at risk. The master scheduler and I assessed the situation and developed a contingency plan. We worked with the supplier to expedite the delivery and adjusted the production schedule to accommodate the delay.

This case study highlights the importance of effective communication and collaboration between the master scheduler and production planner, emphasizing flexibility and adaptability in responding to unexpected challenges. Without the master scheduler’s expertise in creating and adjusting the production schedule, and my role in monitoring and coordinating resources, navigating this situation would have been more difficult.

In summary, the collaboration between the master scheduler and production planner is essential for smooth and efficient production operations. It requires effective communication, problem-solving skills, and a willingness to adapt. Together, we overcome challenges and meet customer demands, contributing to the manufacturing company’s success.

Summary and Final Thoughts

In manufacturing, the roles of a master scheduler and a production planner are crucial for ensuring efficient and effective production processes. While both roles involve developing schedules and plans for production, there are key differences between them.

A master scheduler oversees the overall production schedule and ensures alignment with the company’s strategic goals. They have a big-picture view of the entire production process and work closely with departments to coordinate resources and resolve issues.

In contrast, a production planner focuses on scheduling individual production orders, coordinating suppliers, and monitoring inventory levels.

While these two roles have distinct responsibilities, they are interconnected and rely on each other for successful production planning. The master scheduler provides the long-term vision and strategic direction. The production planner executes the detailed plans daily.

A well-functioning master scheduler-production planner dynamic is essential for optimizing production processes, reducing costs, and meeting customer demands. Companies that invest in strong scheduling and planning capabilities gain a competitive advantage in the manufacturing industry.

Interviews

Interviews are crucial for hiring master schedulers and production planners. Managers should ask targeted questions to evaluate a candidate’s skills, experience, and fit. Questions for master schedulers could center around scheduling and supply chain management knowledge, as well as experience with scheduling software. Situational questions can test problem-solving skills in a fast-paced production environment.

When interviewing candidates for the production planner role, the hiring manager will focus on their attention to detail, organizational skills, and ability to handle pressure. They may ask about the candidate’s knowledge of inventory management and coordinating with different departments.

Communication and interpersonal skills are also important for this role. Collaboration with colleagues and effective communication with stakeholders are essential, so the hiring manager will evaluate the candidate’s ability to communicate clearly and work well in a team.

The interview process allows the hiring manager to identify the candidate’s strengths, weaknesses, and potential for growth in the master scheduler or production planner roles. By asking targeted questions and evaluating the candidate’s responses and behavior, the hiring manager can make an informed decision in selecting the best candidate.

Related Resources

Now that you understand the roles and responsibilities of a master scheduler and production planner, it’s time to take action. Here are some resources to further explore and apply these topics in your own life or situation:

– Books: “Production Planning and Control for Semiconductor Wafer Fabrication Facilities” by Thomas R. Gulledge and “Manufacturing Planning and Control for Supply Chain Management” by F. Robert Jacobs and William Lee Berry are recommended for expanding your knowledge.

– Online courses: Platforms like Coursera, Udemy, and LinkedIn Learning offer a variety of online courses that delve deeper into master scheduling and production planning concepts. Explore these options to find what suits your needs.

Knowledge is power, but how you apply it makes a difference. Reflect on what you’ve learned and consider how to integrate these insights into your work or personal life. Optimize your scheduling and planning to increase productivity, reduce waste, and achieve greater success. Take the next step, explore these resources, embrace effective scheduling and planning, and unlock your potential.